5

Jan

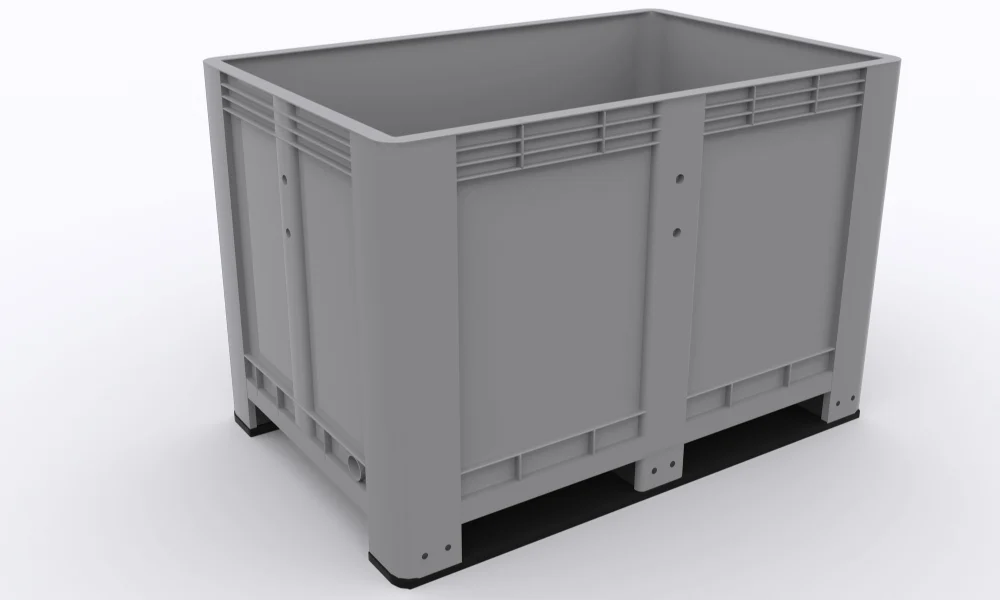

How Plastic Pallet Boxes Improve Supply Chain Efficiency

In today’s fast-paced logistics environment, efficiency is everything. From reducing costs to improving delivery times and minimising waste, businesses are under constant pressure to streamline their supply chains. One simple but highly effective way of achieving this is through the use of plastic pallet boxes.

These durable, reusable containers are designed for heavy-duty storage and transport, offering benefits that extend across every stage of the supply chain. In this article, we’ll explore how plastic pallet boxes improve efficiency, from warehousing and distribution to sustainability and long-term cost savings.

Streamlined Storage and Handling.

One of the key advantages of plastic pallet boxes is their ability to optimise storage space. Many models are stackable or nestable, which allows businesses to make better use of warehouse and vehicle capacity. By reducing wasted space, companies can store more goods in less room, lowering overheads and improving stock management. Nestable designs also minimise return transport costs, as empty boxes take up less space when sent back for reuse.

Additionally, their uniform size and design make them easier to handle using forklifts, pallet trucks, or automated systems, saving time and reducing bottlenecks in busy environments.

Improved Transport Efficiency.

Transporting goods is one of the most resource-intensive aspects of the supply chain. Plastic pallet boxes are designed with strength and lightness in mind, which means they can carry heavy loads without adding unnecessary weight.

This combination reduces fuel consumption and lowers overall shipping costs. The sturdy construction also ensures that goods remain secure during transit, reducing the risk of damage and returns. Unlike wooden alternatives, which may splinter or collapse under strain, plastic pallet boxes provide consistent reliability, helping companies to maintain smoother and more predictable operations.

Consistency for Automated Systems.

As more warehouses adopt automation, consistency in storage equipment has become increasingly important. Plastic pallet boxes are manufactured with precise dimensions and standardised designs, ensuring compatibility with conveyors, robotic pickers, and automated storage and retrieval systems. This standardisation minimises errors and downtime, enabling seamless integration with modern logistics technology. For companies investing in automation, plastic pallet boxes provide the reliability and consistency required to keep systems running at peak efficiency.

Reduced Waste and Longer Lifespan.

Efficiency in the supply chain isn’t just about time and cost; it’s also about minimising waste. Plastic pallet boxes are far more durable than single-use or wooden alternatives, offering a significantly longer service life. They can be reused hundreds of times without losing structural integrity, helping businesses cut down on packaging waste and replacement costs. At the end of their lifecycle, many models can be recycled into new products, further supporting sustainable practices.

This reusability reduces the need for constant purchasing and disposal, which not only saves money but also supports corporate responsibility initiatives.

Hygiene and Compliance.

In industries such as food production, pharmaceuticals, and healthcare, hygiene is a non-negotiable part of supply chain efficiency. Contaminated or damaged packaging can lead to costly delays, product recalls, and reputational damage.

Plastic pallet boxes are easy to clean and sanitise, with smooth, non-porous surfaces that prevent bacteria, mould, or pests from taking hold. This makes them ideal for meeting strict industry standards, while reducing the risk of contamination across the supply chain. By ensuring goods remain safe and hygienic, plastic pallet boxes help businesses avoid unnecessary interruptions and keep products moving without delay.

Lower Long-Term Costs.

Although the initial investment in plastic pallet boxes can be higher than other materials, the long-term cost benefits are clear. Their longer lifespan, reduced maintenance, and efficiency improvements across storage, transport, and handling all contribute to significant savings over time. When paired with reduced product damage, lower fuel costs, and fewer replacements, plastic pallet boxes prove to be an investment that pays back quickly.

Supporting Sustainable Supply Chains.

Sustainability and efficiency often go hand in hand. Plastic pallet boxes contribute to greener supply chains by:

- Reducing reliance on single-use packaging

- Offering long-term reusability

- Being recyclable at the end of their lifecycle

- Helping companies reduce carbon emissions through lighter transport loads

For businesses committed to environmental targets, plastic pallet boxes provide a practical way of achieving efficiency gains while meeting sustainability goals.

From warehouses to transport fleets, plastic pallet boxes offer a wealth of benefits that directly improve supply chain efficiency. Their durability, stackable design, consistent dimensions, and hygienic qualities make them invaluable across a wide range of industries. By reducing waste, lowering costs, and supporting automation and sustainability, plastic pallet boxes prove that even small changes in handling equipment can have a big impact on overall performance.

For companies looking to streamline operations and stay competitive, plastic pallet boxes are a smart, future-ready solution.

Unit 1a & 1b Hammond Avenue

Whitehill Industrial Estate

Stockport

SK4 1PQ

0161 429 7536

sales@reco-group.com